About Boundary Breaker®

Fluids flowing through process equipment inherently encounter friction forces caused by the boundary layer drag which forms on all of the mechanical surfaces in which the flowing fluid contacts.

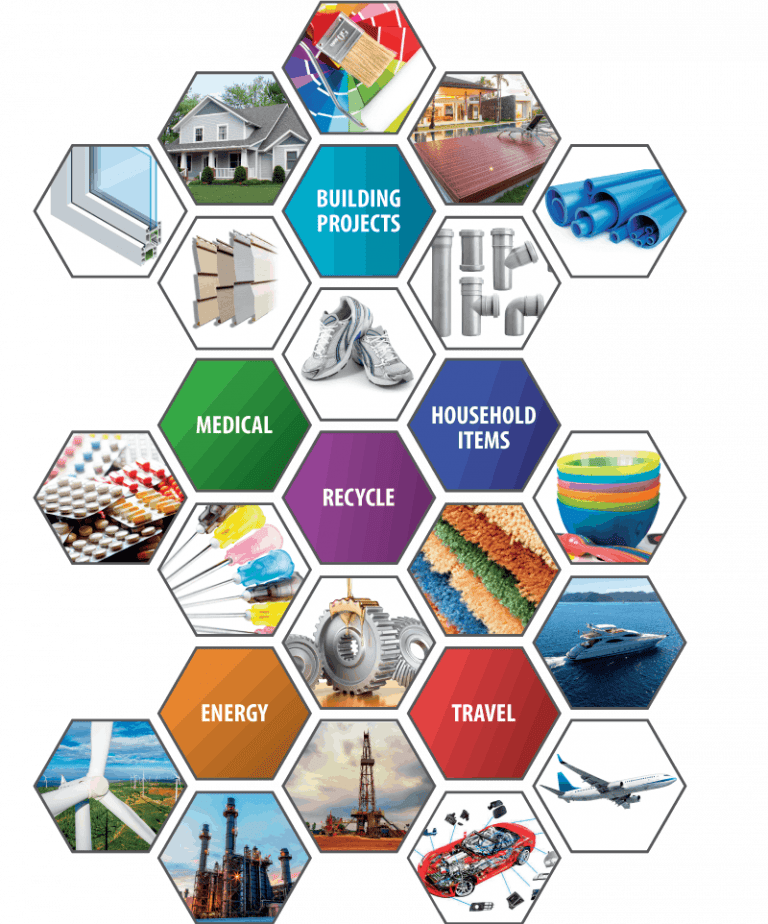

The Boundary Breaker® technology is an engineered structural particle that helps to convert the static friction to kinetic friction thereby reducing energy required for the fluid to flow through the process equipment and increasing productivity. These specialized patented particles interact directly with the boundary layer to help component dispersion.

Boundary Breaker® acts like millions of rolling and tumbling mixing blades to produce enhanced dispersion of conglomerate additives. This allows for reducing additive loading which helps lower formula cost.

Boundary Breaker® is an inert structural particle that is chemically and thermally stable. In its raw form a powder ranging from nano to micron sizes.

Note: Boundary Breaker® limitations in thermoplastics:

- Clear parts will become hazy

- Will not work with extremely high flow materials (example PP above a 50 MFI)

- Does not work producing film below 2 mils in thickness

- Increases formula component dispersion which can reduce expensive additives

- Reduces plate out and die buildup on extrusion

- Improves cellular nucleation, allowing for weight reduction

- Thermally and chemically stable

- Reduces energy consumption throughout the process by lowering drag coefficient

- Chemically inert nano to micron sized powders tailored to the application

- Produces a resin rich surface on filled resins

- Supports a reduction of overall warpage of part

- Loading 0.25% to 5.0 % by weight of total formula depending on application

- FDA – Approved for Food contact and NSF 61 safe for drinking water

- Safe for equipment

- 12%-30% productivity increase with extruders and injection molding equipment