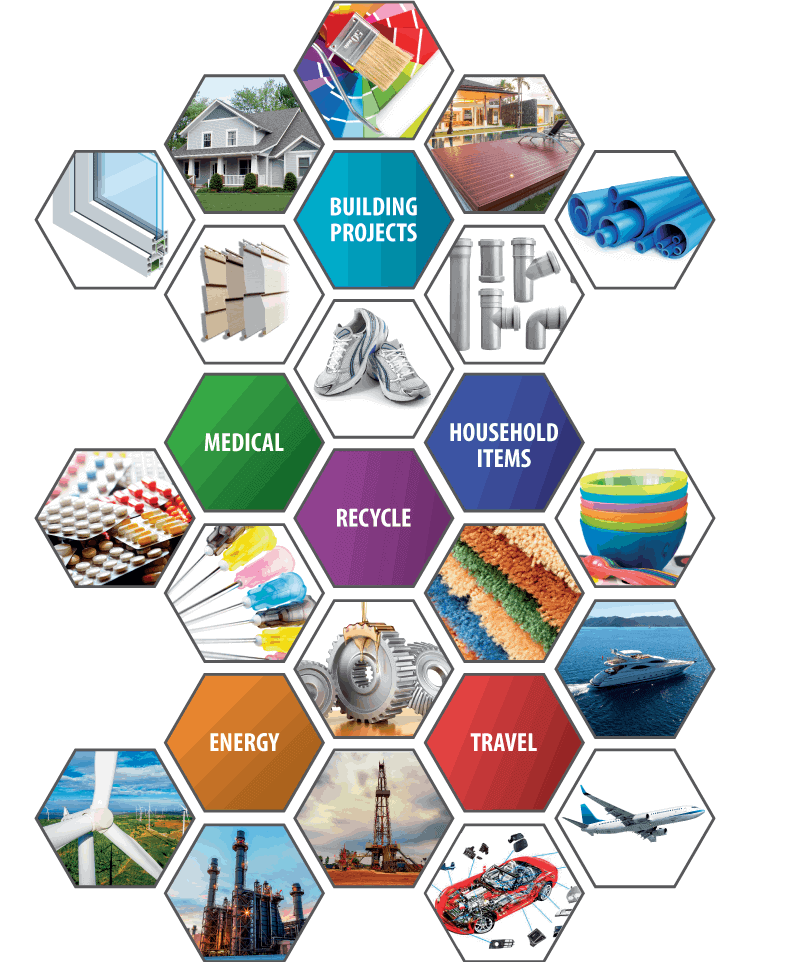

Plastics in Energy Application

Do you want to decrease energy costs for your plastic manufacturing process?

Using BOUNDARY BREAKER® in your thermoplastic applications gives you an enormous edge over your competitors.

Depending on application the throughput can be increased by a staggering 12% – 30%. Formula component dispersion are increased which can reduce the amount of expensive additives thus saving formula costs. Additionally in foamed products the improved cellular nucleation allows for a weight reduction while maintaining physicals.

ECOPURO’S® core value is a sustainable approach for all our technologies. With BOUNDARY BREAKER® you reduce energy consumption throughout the process by lowering the drag coefficient. Can you imagine the amount of CO2reduction globally if the plastics industry reduced energy by 10% – 25%?

Studies have shown that BOUNDARY BREAKER® is safe for manufacturing equipment and helps to reduce overall warpage of parts. It is also FDA approved for direct food contact and safe for drinking water having passed NSF 61.

Decrease Energy Costs

Energy Applications

Boundary Breaker® Benefits

- Reduces Kilowatts per linear foot

- More parts per Kilowatt in injection molding

- Reduces companies CO2 footprint

- Saves energy cost by 10%-25%